Product Center

Product Center

Contact us

Service Hotline

Address: 4th and 5th Floor, South Gate, Building D, Jindao Park, Tongxin Industrial Park, No.179 Huizhi Middle Road, Lugu National High-tech Industrial Development Zone, Changsha City, Hunan Province

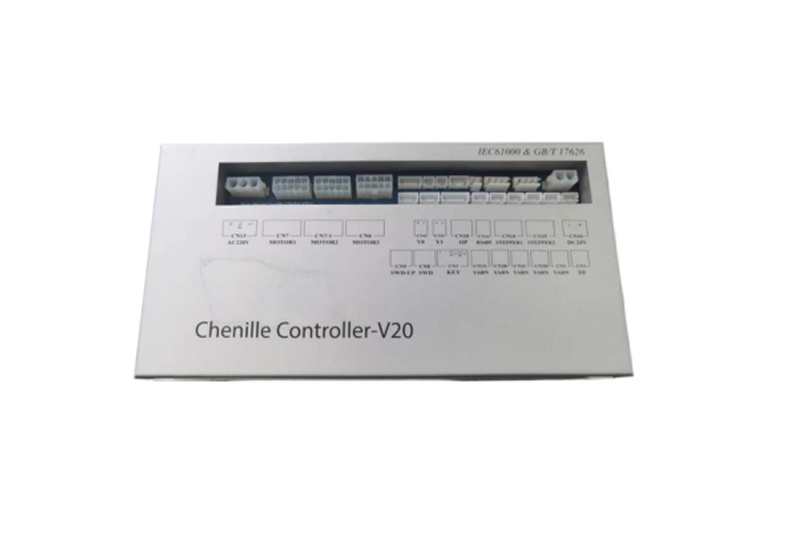

Crochet machine control system

This product aims at the vacancy of domestic electronic intelligent crochet machine, replacing the flower chain chip box of the traditional mechanical crochet machine with a servo motor. Each axis is independently controlled by a single servo motor. Pattern files are stored in the control system. Theoretically, there is almost no upper limit on the number of wefts, and software can be used to make patterns on the computer.

The system is highly integrated with high-speed brushless motor and stepping motor drive control technology. At the same time, the motor closed-loop control algorithm is introduced. The machine transmission part is driven independently by the motor and can adjust the speed steplessly. The production efficiency is high, meeting various spinning forming requirements, and solving the problems of large spindle difference, high noise, low yarn quality, etc. caused by the belt transmission of the transmission machine.

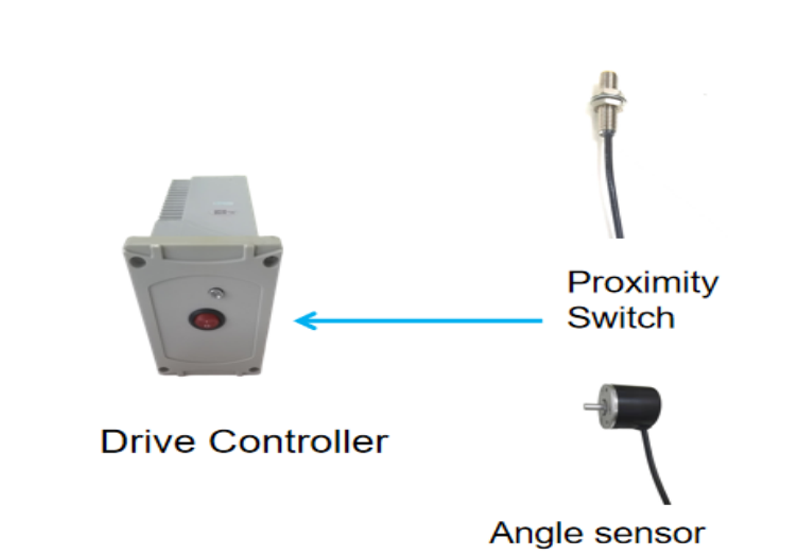

Digital winding and ranging control system

The system highly integrates high-speed precision servo, brushless DC, stepping motor drive control technology, and introduces high-speed traverse servo yarn guide motion control and online constant tension closed-loop control algorithm. It has been widely used in the winding and traverse winding control of spinning winding equipment such as precision winding winders, stranders, doubling machines, and air wrapping machines to achieve highly flexible digital winding functions, It improves the winding performance and package quality of the machine, and is the best choice for yarn winding equipment.

According to the winding process characteristics of the winding equipment of the plastic wire drawing unit, our company integrates many technologies such as constant tension system and field bus communication, and adjusts the speed of the winding motor in real time through the change of the tension sensor, so as to ensure the uniform tightness and tightness of the winding forming and meet the user's needs.

Air yarn machine control system

This product combines many years of experience in the field of textile machine motion control, integrates brushless motor, stepping motor and servo motor control technology into a whole, and realizes multi motor linkage through bus technology to meet the process requirements of the hair spraying machine.

The system adopts advanced microprocessor, through precise control algorithm, directly drives the DC brushless motor to drive the grooved drum to rotate, and automatically adjusts the motor speed intermittently, so that there is a slight slip between the bobbin and the grooved drum, and there is an offset between the grooved drum yarn guide slot and the actual winding yarn layer, so as to avoid yarn overlap and achieve the effect of loose yarn formation.

Glass fiber winding machine control system

This product is characterized by single ingot independent electric ingot and advanced DC brushless motor, which realizes the perfect combination of individual control of each ingot and centralized control of the whole machine. It adopts computer digital control, uses computer editing input to control the lifting and step-up of ring plate, arbitrarily adjust twist and spindle speed, and has the advantages of strong overload capacity, energy saving and noise reduction.

On the basis of the existing winding control system technology, the system uses high-precision thread breaking sensor and motor brake technology to ensure that the tail yarn is short when the multi strand yarn is folded and broken, and improve the process requirements and production efficiency.

Electronic scale weighing system

The electronic scale belongs to a kind of weighing instrument. It is a tool to measure the mass of an object by using Hooke's law or the lever balance principle of force. The electronic scale is mainly composed of three parts: load bearing system (scale body), force transfer conversion system (sensor) and indication system (digital display). The electronic scale designed for the winding machine industry can accurately quantify each spindle of yarn