Product Center

Contact us

Service Hotline

Address: 4th and 5th Floor, South Gate, Building D, Jindao Park, Tongxin Industrial Park, No.179 Huizhi Middle Road, Lugu National High-tech Industrial Development Zone, Changsha City, Hunan Province

Winder control system

Key words:

Classification:

Product Description

Product overview:

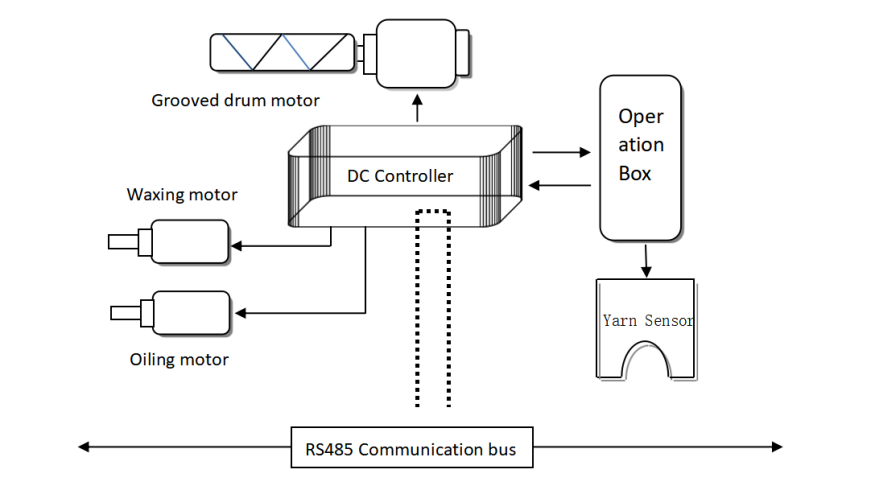

The system adopts advanced microprocessor, through precise control algorithm, directly drives the DC brushless motor to drive the grooved drum to rotate, and automatically adjusts the motor speed intermittently, so that there is a slight slip between the bobbin and the grooved drum, and there is an offset between the grooved drum yarn guide slot and the actual winding yarn layer, so as to avoid yarn overlap and achieve the effect of loose yarn formation.

Product characteristics:

1. Human computer interaction, real-time display of various state parameters during bobbin winding, and editing of process and machine configuration parameters

2. DC speed regulation control is adopted, which is more energy saving and power saving than traditional AC control, and saves 1/3 of the power cost for winding machine users. The system has its own motor brake function

3. The transmission mode is single spindle and single control. The single spindle speed can be set by itself. Different spinning processes can be used for different spindle positions to meet different user needs

4. The electronic anti overlap is adopted, and the anti overlap parameters are adjustable, so as to meet the same tightness when different yarns are formed, ensure uniform yarn dyeing, and improve yarn quality

5. Winding speed, control range 100-1200 m/min, maximum upper limit speed can be set to prevent yarn blocking workers from modifying the winding speed without permission to affect yarn forming

6. Single spindle tachometer length, full cylinder automatic shutdown, yarn breakage automatic shutdown alarm, prompt yarn blocking workers to carry out the next process operation, and improve production capacity

7. Constant speed control of waxing and oiling motor to ensure yarn quality

8. Fault protection, multiple measures, such as abnormal alarm, motor overspeed, hardware failure, etc

Product advantages:

1. Cost advantage: Compared with traditional schemes, frequency converter, relay, speed sensor are eliminated, wiring is simple, and production efficiency is high

2. High efficiency and energy saving: the energy consumption of direct drive energy-saving motor is reduced by 30%

3. Precise length setting: 3-way Hall sensor collects motor speed

Control diagram:

Related Products

undefined

Leave a message